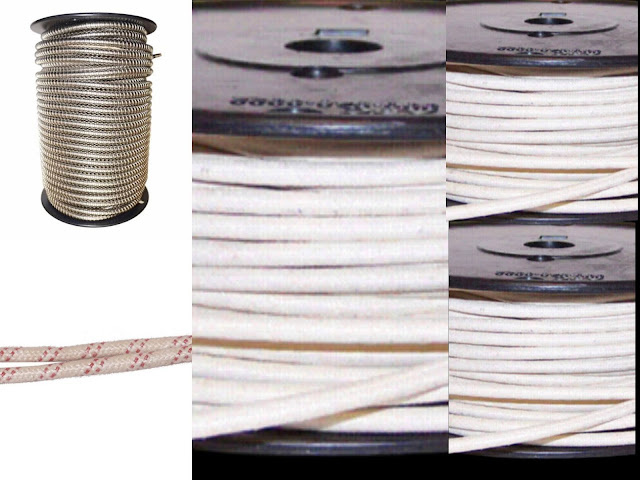

Heater wires in which resistance wires are twisted in a spiral shape around a core filament, an additional intermediate layer is framed by molding, and afterward, the second layer of resistance wires is wound, and insulating treatment is performed with PVC resin.

Safe and reliable heater wires

consolidating temperature identification with safety and protection components,

which can be utilized for a wide scope of heating applications.

Three different types of heater wire are used for heating applications

·

Copper wire for control panels

·

Nichrome (NiCr) wire for heaters

·

Thermocouple wires

Among the list of products, the

Extruder Supplies additionally offers great thermocouples and heater wires.

They assume a vital role in the operation and numerous different processes in

the plastic industry.

Extruder Supplies offers a great

PVC Jacket and Teflon Jacket and Fiberglass Jacket thermocouple wires just as

protection link, TGGT Heater wire, and Fiberglass sleeves.

Our effective temperature and

heater wires withstand high temperatures for nonstop force supply to different

coordinated units for unrivaled execution. A fundamental feature of this sort

of wire incorporates the capacity to withstand high temperatures, vibration,

and pressing factors. Extruder Supplies, since 2005, is effectively engaged

with the stockpile of heating application machine parts made of high-grade

materials and executed tough quality control checks before dispatching them to

the clients.

To know more details about the

spare parts, clients can request their quote and the Extruder support team will

get back to you as quickly as possible.

All the spare parts are available

at the Extruder Supplies online store at reasonable rates.